An international team of researchers led by Associate Professor Jung Ho Kim from the University of Wollongong’s Institute for Superconducting and Electronic Materials(ISEM)have developed a promising new approach to developing silicon-based lithium ion batteries.

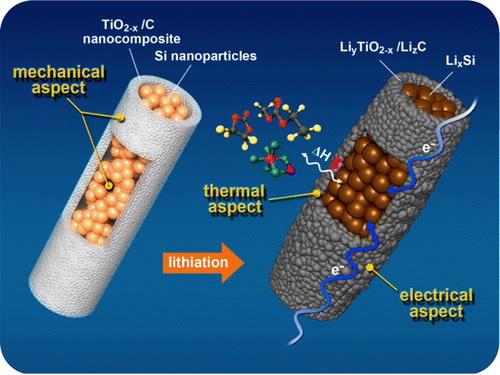

Using electrospinning, a technique where an electrical charge is used to draw very fine fibres from a liquid, the team has developed a core-shell structured microfiber composite that gives the lithium ion battery the potential to charge more quickly, hold their charge for longer and have a longer life.

Previously silicon-based battery anode materials have suffered from safety concerns but they were much more attractive as they theoretically possessed higher capacity than graphite meaning greater battery capacity and longer life-cycles – two key elements that need to be advanced to allow for greater commercial applications of lithium ion batteries.

The technique developed by the team allows for a protective layer of black titanium oxide(TiO2-X)to be spun into the battery anode that retards the reaction between the silicon and the battery electrolytes without compromising the performance of the battery.

“The results of our research provide a new direction for lithium ion and potentially other energy storage materials as black titanium oxide may prove to be an exciting alternative to carbon.

“Globally researchers have been working on battery materials that are safe, provide high energy densities and allow for longer battery lives and we believe that our findings can take battery research in a new and exciting direction”, Associate Professor Jung Ho Kim said.

The team synthesized the core-shell fibrous composite using a dual-nozzle electrospinning technique. The result was a core-shell composite that exhibited the high reversible capacity(~1000 mAh g-1 at 1C rate), the excellent rate-capability(~940 mAh g-1 at 12C rate), and the improved capacity retention in cycling with the low expansion ratio of the electrode.

Leader of the Vehicle Electrification Program of the Australian Automotive Cooperative Research Centre(AutoCRC)and ISEM Director Professor Shi Xue Dou said that this has a great contribution to the advance of lithium ion batteries for electric vehicles.

“The material design concepts involved in this work are general which may allow them to be extended to other materials with high energy densities and importantly the technique can be scaled up for mass production.

“This means that we may be able to use the approach to assist in the development of the next generation of batteries such as lithium-metal based batteries or sodium ion batteries”, he said.

The Institute for Superconducting and Electronic Materials, located at the University of Wollongong’s Australian Institute for Innovative Materials facility, ranks in the global top 10 research groups advancing the development of lithium ion batteries.

This work was recently published in ACS Nano and funded in part by both the AutoCRC and an Australian Research Council Discovery Project. The article is available at http://pubs.acs.org/doi/abs/10.1021/nn500278q

Image:A core–shell structured Si nanoparticles@TiO2–x/C mesoporous microfiber composite has been synthesized by an electrospinning method.